Glass Standoff Glass Railing

The Glass Standoff Glass Railing

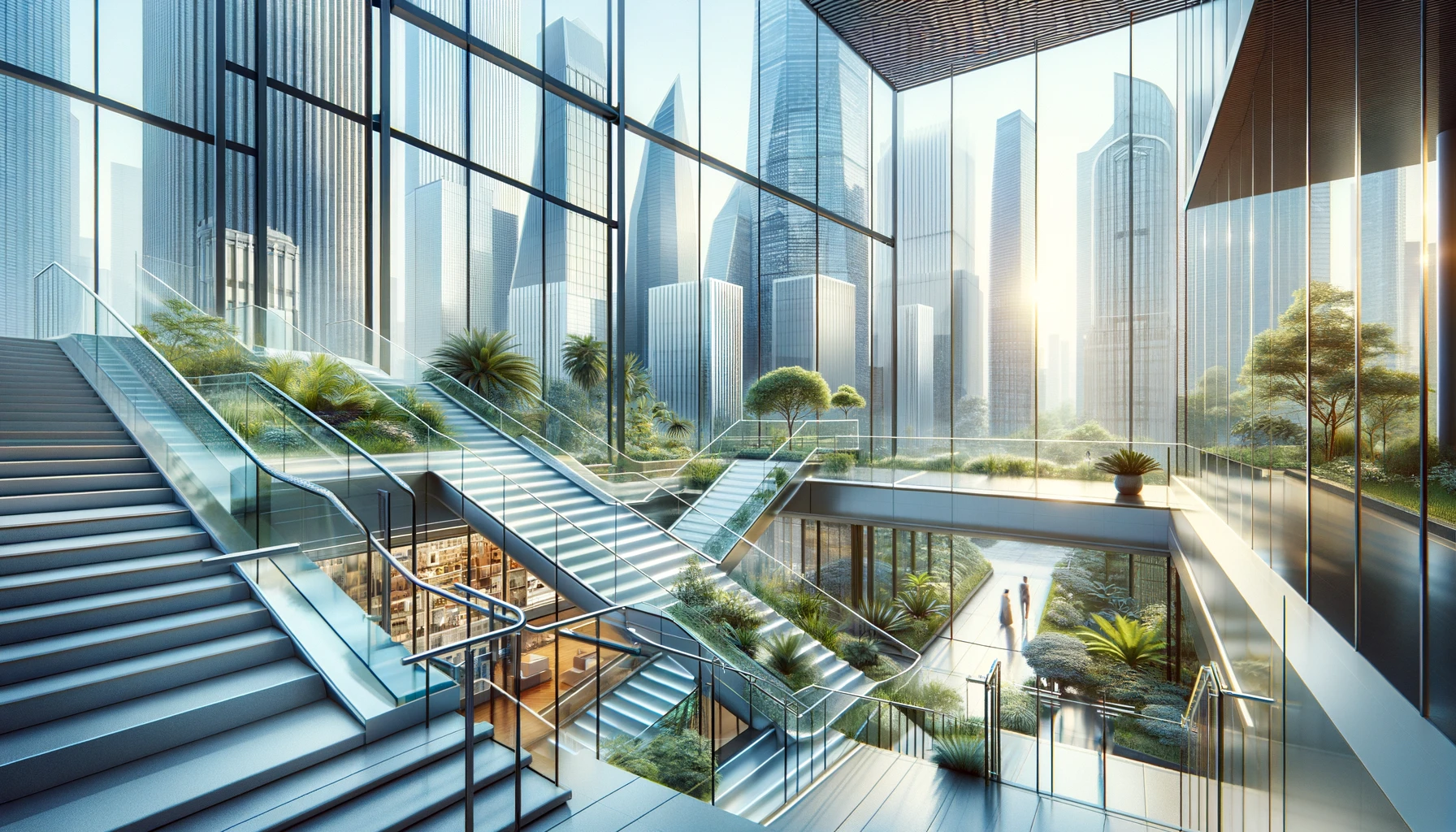

The Glass Standoff Glass Railing system is a sleek and open railing solution that allows full appreciation of the view beyond. Composed of high-quality stainless steel glass point-fixings and tempered glass, this design provides almost unobstructed sight-lines while offering solid support. The system is easy to maintain and can serve as a sophisticated, modern, and attractive design element in both residential and commercial spaces.

Stainless Steel Standoff

Stainless Steel Material:

Let’s delve into the distinctive characteristics and applications of four frequently encountered types of stainless steel: 201, 304, 316, and 440:

201 Stainless Steel: Recognized as a cost-effective variation of stainless steel, the 201 grade contains a lower amount of nickel, making it a more affordable option. However, its heat and corrosion resistance are comparatively weaker, which limits its application to environments that are not overly corrosive or high in temperature.

304 Stainless Steel: Commonly known as the workhorse of stainless steel, the 304 grade boasts commendable heat and corrosion resistance. This type of stainless steel, often used in our products, can withstand most environments effectively, but its durability might be compromised in settings with high levels of salt or chlorine.

316 Stainless Steel: What sets 316 stainless steel apart is the added molybdenum, which endows it with enhanced corrosion resistance, especially in environments prone to chemical corrosion or high salt and chlorine levels. This type of stainless steel, another material we frequently use, may come with a slightly higher price tag than 304, but its superior durability and resistance to corrosion make it a perfect match for more challenging conditions.

440 Stainless Steel: Characterized by a higher carbon content, the 440-grade stainless steel is often utilized in the creation of high-quality cutlery and cutting tools. Although it is exceptionally hard, its corrosion resistance is slightly inferior in comparison.

Stainless steel, renowned for its sleek and polished look, conveys an undeniable sense of superior quality. However, determining the grade of stainless steel by mere appearance is an impossibility. Despite sharing a similar façade, their internal chemical composition and characteristics can vary dramatically. The accurate identification of a stainless steel grade requires specialized chemical or mechanical testing.

Additionally, stainless steel’s versatility in color may come as a surprise to many. While its native, silvery hue is the most frequently seen, stainless steel can be treated to display a plethora of other colors. Techniques in surface treatment allow for an assortment of colors ranging from the classic silver-grey, the profound black, the opulent gold, to the unique rose gold, to name but a few. This color diversity ensures stainless steel’s compatibility with a variety of design aesthetics and décor styles.

Stainless Steel Standoff Style:

Glass spigots play a critical role in a glass railing system, performing the following functions:

Supportive Function: Glass spigots serve as part of the support structure, helping to support and secure the glass panels, ensuring the stability of the railing.

Safety Function: Glass spigots ensure that the glass is firmly fixed in its place, preventing any displacement or falling off of the glass panels, through precise design and manufacturing.

Aesthetic Function: The design and material of the glass spigots themselves add decorative appeal, enhancing the overall aesthetics of the glass railing.

Customizable Function: Depending on project requirements, glass spigots can come in various styles and finishes to accommodate different design styles.

Tempered Glass

Common Tempered Glass:

Tempered glass, a type of safety glass, undergoes a unique heat treatment process to significantly enhance its strength. What sets it apart is that it crumbles into small, granular chunks rather than sharp shards when broken, greatly mitigating the risk of injury.

Boasting a strength 3-5 times that of standard glass and improved thermal resistance—capable of enduring a temperature variance of close to 300 degrees—tempered glass proves especially suited to situations demanding heightened safety and durability, such as in the case of glass railings.

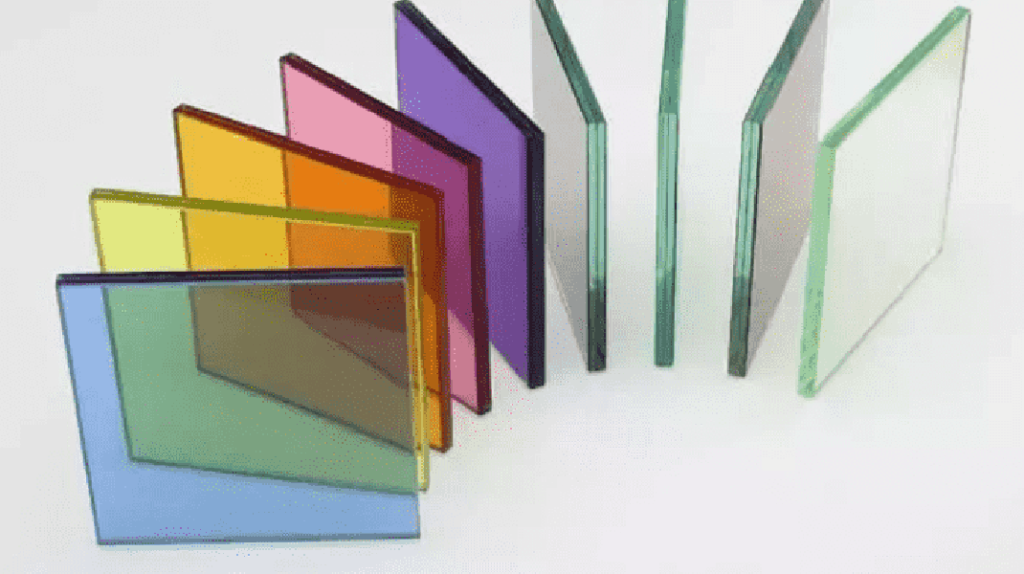

Reflective Glass:

Reflective glass, also known as low-e glass, is a type of glass that’s coated with one or more layers of metallic or other compounds, resulting in a high level of reflectivity. Besides its decorative function that enhances the aesthetic appeal of buildings, reflective glass also improves the visibility and transparency of the glass, minimizes direct sunlight, and maintains indoor comfort. For our glass railings with columns, we offer reflective glass in an array of colors including, but not limited to, bronze, blue, and grey, to cater to your design preferences.

Thickness:

Tempered glass, enhanced through specialized treatment processes, can be tailored in a variety of ways to cater to the distinct needs of diverse projects and customers. For our glass railings, we typically offer tempered glass in a selection of thicknesses such as 6+6mm double-layered glass, 8+8mm double-layered glass, 10mm, 12mm, and 16mm, presenting a multitude of options to adapt to varying environmental and structural demands.

Various Color:

In addition to the standard clear variant, tempered glass is also available in an assortment of colors. We can supply tempered glass in diverse hues like green, blue, grey, and tea color. This array of choices ensures that our glass railings can seamlessly integrate into any decorative design scheme.

Shape:

Depending on its application and design needs, glass railings can take various shapes. Straight glass railings are suitable for linear designs, while curved glass perfectly fits curves or circular designs. In addition, parallelogram glass can be chosen for special angle requirements. For unique designs, irregularly shaped glass can provide the greatest design flexibility.

Advantage and Project Show

Minimalist Design: Our Glass Point-Fixed Glass Railings adopt a minimalist design philosophy. The frameless design not only achieves transparency in spatial perception, but it also creates an unobstructed view for both indoor and outdoor environments. Moreover, its elegant style can adapt to a variety of modern architectural designs, perfectly blending interior and exterior spaces.

Material Advantages: With high-strength stainless steel as the glass point fixings, they have excellent corrosion resistance and anti-oxidation properties, maintaining their original luster and aesthetic appeal in various weather conditions. The use of safety glass also provides extra security for users, minimizing the risk of scratches even in extreme situations of breakage.

Easy Installation: Owing to its simplistic design, the installation process of the Glass Point-Fixed Glass Railings is relatively effortless. There’s no need for complicated tools or specialized technicians, as the installation can be completed with just a few simple steps.

Simple Maintenance: Compared to traditional railings, maintenance of Glass Point-Fixed Glass Railings is much simpler. Regular cleaning of the glass and stainless steel parts is all that’s needed to maintain its long-lasting aesthetics.

Customization: We can offer glass in a variety of shapes, sizes, and colors to cater to your needs, allowing our railings to perfectly blend into your decorative design.

The Glass Standoff Glass Railing Installation Guidance

- Planning & Measurement: Evaluate layout and measure the area for point-fixed glass railing installation. Calculate the needed glass panels and stand-offs.

- Materials & Tools Preparation: Check all stand-offs, glass panels, and fasteners for damage. Gather necessary tools.

- Surface Preparation: Mark positions for stand-offs on the wall, staircase, or steel frame and drill holes.

- Stand-off Installation: Install and secure the first part of the stand-offs into drilled holes, ensuring level and alignment.

- Glass Panel Installation: Align glass panels over the installed part of the stand-offs. This may require two people.

- Securing Glass: Attach the second part of stand-offs, securing the glass panels in place. Ensure tight fastening.

- Post-Installation Check: Ensure panels are evenly placed and the structure is balanced. Recheck all fasteners and connections.

Remember to refer to the manufacturer’s guidelines for specific instructions and prioritize safety during installation. Seek professional help if needed.

Elevate your space with Walt Railing's sleek glass railings

Get In Touch With Us!

Phone

+ 86-134 3484 9110

info@waltrailing.com

Address

A61, Floor 15th, Building T5, Smart New Town, No. 26, Jihua Road, Chancheng, Foshan, Guangdong, China